MANIAGO, CITY OF KNIVES

The nobleman Nicolò di Maniago had the waters of the Còlvera creek channelled into a ditch in order to irrigate the crops south of the town, and to exploit the hydraulic energy in the mills, sawmills and smithies built along its course.

Blacksmiths immediately realise the benefits that water energy provides in terms of production and labour. In the smithies they produce sharp tools for farmers and woodcutters, as well as cutlasses, swords and other polearms for the Most Serene Republic of Venice.

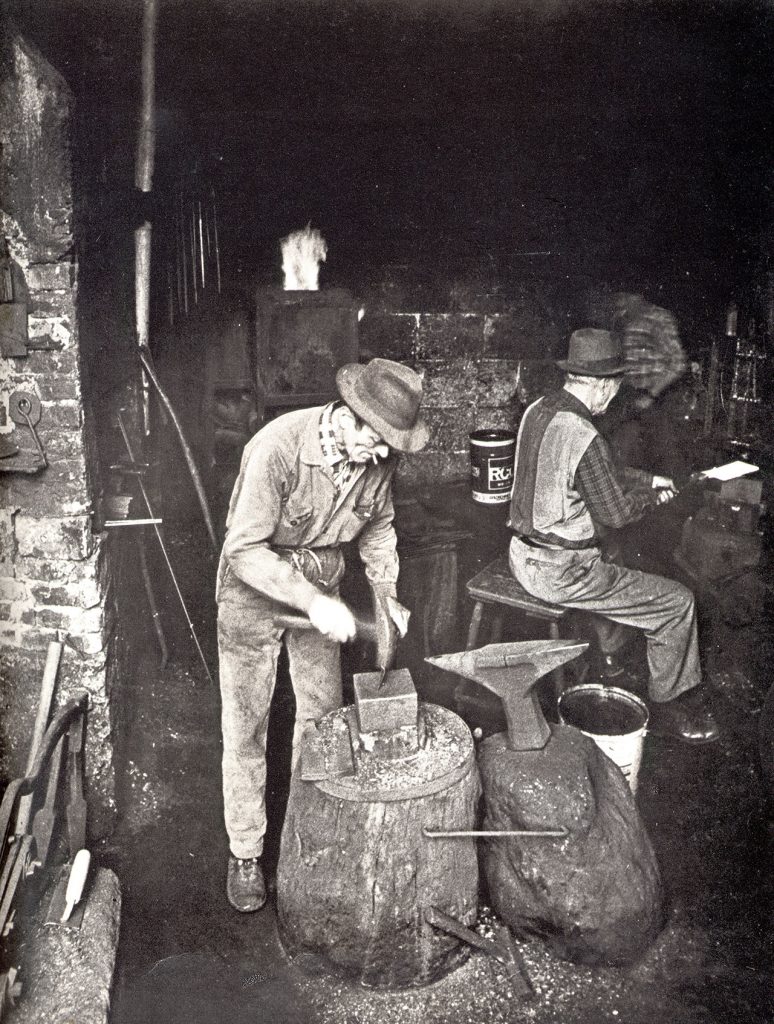

Blacksmiths working in Maniago smithies were called favri da gros (Friulian, lit. rough smith), a name that recalls the unrefined finish of the objects manufactured. What mattered was just their sharpness, to serve their purpose.

The long tradition of blacksmiths in Maniago is therefore not tied to the local availability of raw materials, but it is a story of energy: the energy of water, an element that defines this portion of Pordenone foothills.

A change in the production and work happens around the 18th century, when the demand is also for smaller, more finished and precise cutting tools.

The technology and the very image of Maniago blacksmiths changes and the favri da fin (Friulian, lit. fine blacksmith) appears. Not just function, but also aesthetics and form are of great importance in his work.

All the favri da fin needs are a forge, a grindstone and a workbench. He no longer needs the water canal to power the mallet, therefore craft workshops spring up almost everywhere in town.

Production is focused on scissors, pocket knives, table knives, surgical tools and other professional instruments.

In the early 1900s, the first large factories are founded. Thanks to electrically-powered machines, it is possible to mass-produce cutting objects with less effort and in less time.

Maniago first plant, the Co.Ri.Ca.Ma. (United Knives Factories of Caslino and Maniago), is founded in 1907 by Albert Marx, a German entrepreneur, who owns other plants in Solingen (Germany) and Casilino (near Como).

This is the beginning of what is considered by the people of Maniago the plant. The factory is built a few steps away from the town’s main square, Piazza Italia: a modern building, unprecedented both in town and in the surrounding area. Here, for the first time, the production of cutting tools is carried out by electrically-powered machines. The efficiency of mechanisation is combined with the know-how and manual skills of local craftsmen, creating a connection that will profoundly affect the future structure of all production units.

Today, the restored Co.Ri.Ca.Ma. building is home to the Museum of Blacksmiths’ Art and Cutlery.

The “Maniago model” rather than producing blades linked to a specific tradition or type, has always been mainly focused on new developments and on market demands, through a very precise commercial policy and approach to production: as a matter of fact, by the end of the 19th century, Maniago produced more than 1,000 different types of knives and penknives.

Having the market as main focus entails great adaptability to the present and a vision for the future and is the key feature that enables Maniago to be the Italian capital and world industry leader.

The variety of products manufactured, although set in a completely changed production context, is a reality to this day, so much so that Maniago rather than city of knives, should be called city of blades. Traditional productions, enhanced by research, new materials and a focus on design, have been joined by new areas of development such as skate blades, blades for the food industry, corkscrews, and even swords and edged weapons for collectors and movie productions, all the way up to components for gas and steam turbines and aerostructures: all deeply rooted in and originating from the expertise gained in manufacturing cutting tools.

Over the last 30 years, due to globalisation and international competition, companies have been driven to choose quality over quantity, also exploiting the appeal of the ‘Made in Italy’ trademark. This has undoubtedly had an impact on the number of companies and employees, but also encouraged greater specialisation in production and collaboration between companies.

Today, there are about 70 plants in Maniago producing cutting tools: these are small and medium-sized production units, which annual turnover is largely accounted for by substantial exports, especially to the U.S., German, French and northern European markets.